The Potential Transformers are tailor-made, to suit to individual customer’s requirement. C.R.G.O. Laminations are procured to the required sizes. Over the Laminations secondary , primary winding & Insulation and two layers each of cotton tape and empire tape is wound as basic insulation.

After basic insulation, required number of secondary turns using super enamelled copper wire is wound on the toroidal coil winding machine. The different secondary cores of the transformer are wound separately. The number of cores per transformers will be as per requirement of the customer. After winding all cores individually, these cores are stacked together and all secondary leads are bunched together, brought out through a chimney which is fixed to the cores.

The secondary coil is now ready for H.T. Insulation. The insulation is carried out using kraft paper; thickness of insulation depends on the rating of the transformer.

After H.T. Insulation, the core is wound with required number of primary conductors using double cotton covered copper / aluminium wire. After primary windings, the end of the conductors is crimped with suitable lugs for termination.

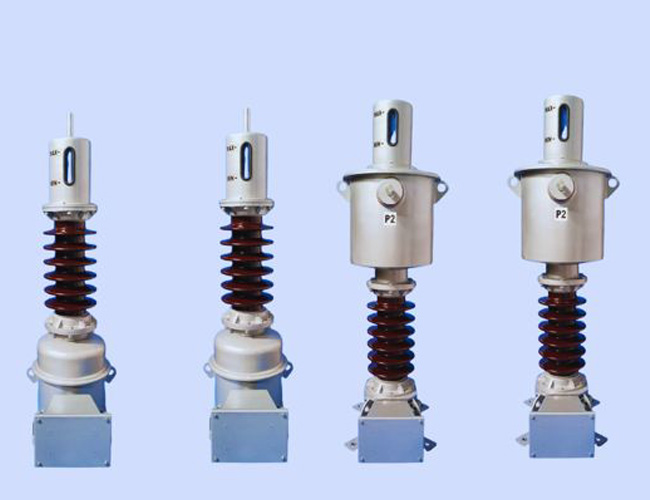

The core now housed inside the top tank of the tank assembly, which consists of bottom tank, porcelain bushing and top tank. The secondary leads are passed through the porcelain to be terminated at the bottom tank.

The entire assembly is no subjected to vacuum and filled with oil after which final assembly is completed. The transformers are now subjected to all routine tests as per I.S. and can then be offered for inspection and despatch.

Potential transformers are also known as voltage step-down transformers or voltage transformers, in which the voltage of a circuit is reduced to a low voltage.

| Brief performance data of Potential Transformer | |

|---|---|

| Installation | Outdoor |

| Design | Inductive Type |

| Insulation | Oil-paper |

| Highest Voltage for equipment | 11 – 245 kV |

| Voltage factor (Vf) | Up to 1.2 Continuous and 1.5 for 30 Sec |

| Insulators | Porcelain/Polymer |

| Creepage distance | Standard - 25mm/kV Longer on request |

| Ambient Temperature | -5° C to +50°C , as per customer requirement |

| Design Altitude | Max. 1000m , as per customer requirement |

| Accuracy | Meets all IEC & IS metering & Protection classes |

ORGANIZATION

CERTIFIED TO

ISO 9001:2015

WhatsApp us